Introduction: The New Standard for Efficient Commercial Design

In the competitive landscape of commercial real estate and multi-family development, efficiency, safety, and compliance are paramount. Traditional wood and gas fireplaces introduce costly ventilation, complex flues, and strict fire code clearance requirements.

This comprehensive guide is designed for architects, interior designers, and project specifiers, detailing how Zero Clearance (ZC) Electric Fireplaces offer a fast, safe, and code-compliant solution for modern project integration.

Ⅰ. Zero Clearance Decoded: Why Electric Fireplaces are Inherently Safe

The Technical Definition and Quantified Safety of Zero Clearance

Zero Clearance (ZC) refers to a unit’s ability to be installed with its enclosure in direct contact with combustible construction materials (like wood framing or drywall) without posing a fire hazard.

For our electric fireplace inserts, ZC is a core safety feature:

- Core Safety Mechanism: Overheat Protection Our inserts are equipped with a sensitive, built-in overheat protection system. When the internal motor core temperature reaches between 85℃ and 105℃, this system instantly triggers a shutdown. This prevents damage to internal components and enhances safety.

- Quantified Shell Temperature: Safe-to-Touch Crucially, even when the internal core reaches approximately 90℃, the external casing temperature typically remains around 40℃ (or 104℉). This temperature is well within the safe-to-touch range for occupants and significantly below the ignition point of any standard building material, validating our Zero Clearance design.

Key Comparison: The ZC Electric Advantage (Time and Cost Savings)

|

Feature |

ZC Electric Fireplace Insert |

Traditional Gas Fireplace (ZC} or Non - ZC) |

B2B Focus: Savings & Benefits |

|

Framing Gap |

Direct contact (Zero Clearance) |

Requires strict insulation/air gaps, often 12” or more. |

Saves:Simplifies framing, reduces material and labor costs. |

|

Venting |

100% Ventless (No chimney or flue required) |

Requires complex flue or venting system. |

Saves:Eliminates expensive roofing and HVAC work. |

|

Trades Required |

Standard Electrician, Finish Carpenter |

Gas Plumber, Vent Specialist, Electrician |

Benefit:Streamlined scheduling and procurement. |

|

Safety Approval |

CE, GS, CB Electrical Safety Certified |

ANSI or CSA Combustion Certification |

Benefit:International approval, faster project sign-off. |

Ⅱ. Technical Specifications: Mastering Dimensions and Integration

Precision Installation: Best Practices for Rough Opening Dimensions

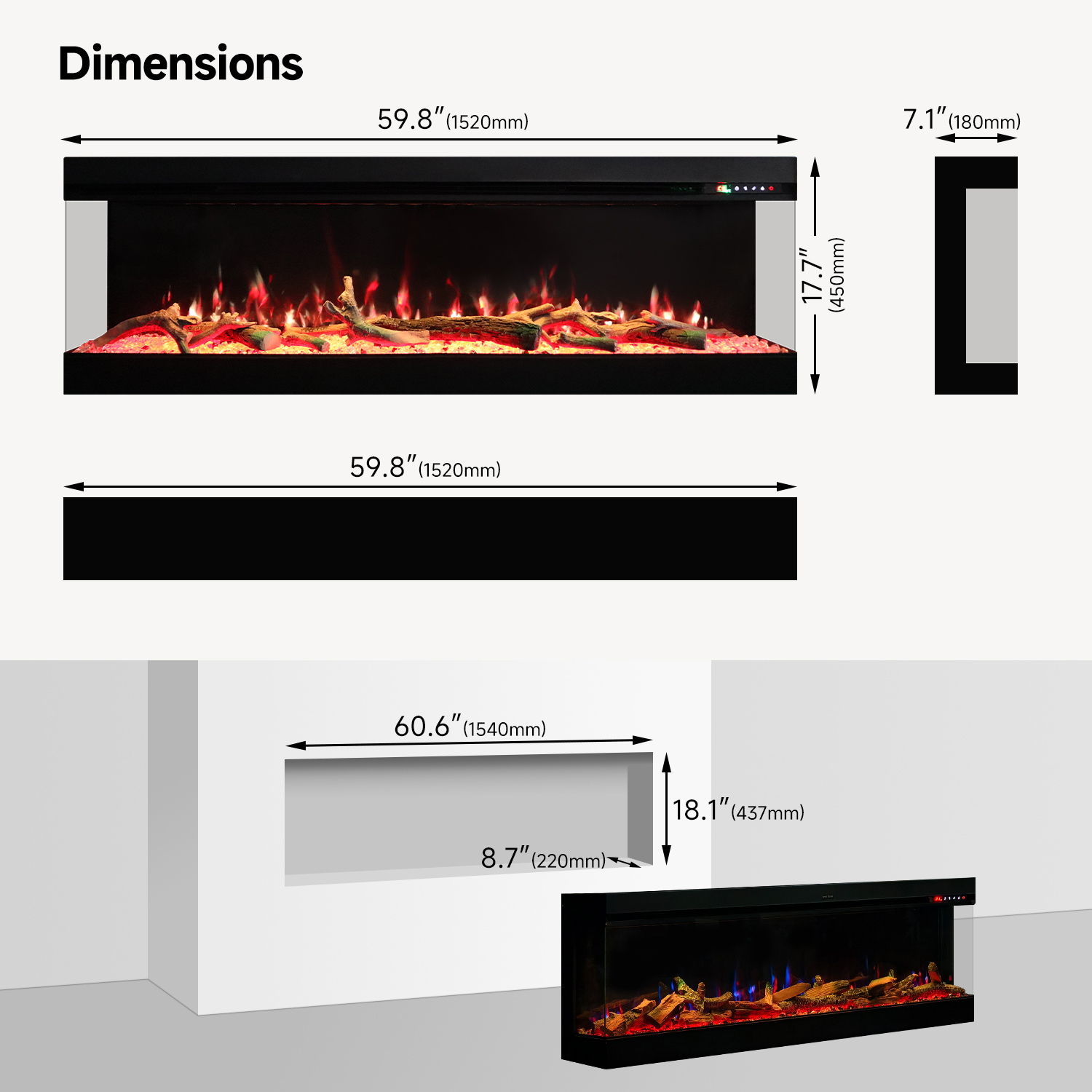

Accurate dimensions are critical for seamless integration. We recommend the following Rough Opening (RO) Best Practices to ensure ease of installation and a flawless flush-mount finish:

|

Dimension |

Recommended RO Size |

Purpose and B2B Value |

|

Width |

Unit Width + 2cm |

Provides 1cm clearance on each side for the insert to slide in easily and allows for minor leveling adjustments. |

|

Height |

Unit Height + 2cm |

Provides 1cm clearance above/below for vertical adjustment. This gap is hidden by the finishing trim. |

|

Depth |

Unit Depth + 4cm |

Ensures ample room for electrical wiring, securing the unit, and accommodating a standard wall outlet behind the unit (as ZC allows). |

- Actionable Tip: Always consult our precise CAD drawings. By adhering to the +2 / +4cm rule, you will significantly reduce the risk of costly on-site modifications.

Electrical and Design Flexibility

- Power Requirements: Our units are supported by robust plug certifications (SPT, SVT-SJTW) ensuring wiring safety. While most are 120V, high – BTU models may require a dedicated 240V, high – BTU line, which should be planned with the electrical team early on.

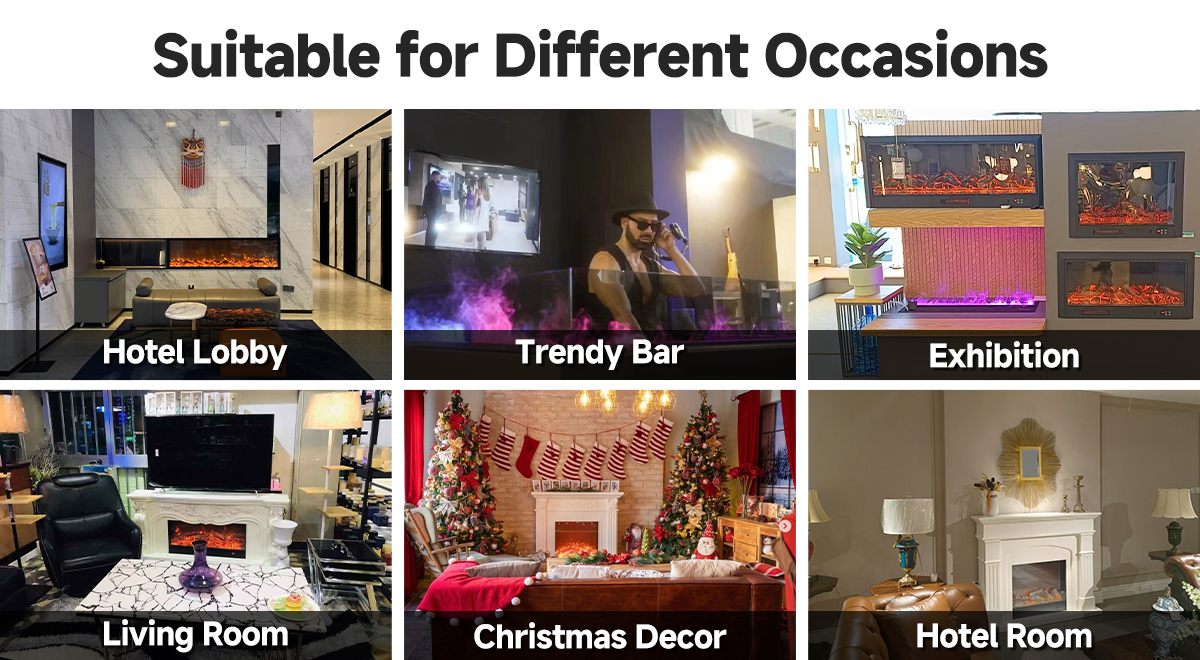

- Design Options:Our ZC design allows for flexible integration of linear, 3-sided, and see-through models into any internal partition wall, maximizing design impact.

- Smart Integration:High-end units feature Wi-Fi and RF control, enabling seamless integration with hotel BMS (Building Management Systems) or smart home platforms for energy management.

Ⅲ. Simplified Installation Protocol: Saving Time and Money

The ZC Three-Step Installation

The ZC design dramatically simplifies the construction process:

- Prepare the Rough Opening: Construct a standard wood or metal frame using the +2cm / +4cm rule. Crucially:No additional fireproofing or insulation is required.

- Electrical Hookup: Slide the insert into the frame. Complete the hardwiring or plug-in connection, utilizing the generous $4\text{cm}$ depth clearance for effortless wiring access.

- Finish the Surround:Apply the finishing material (drywall, stone, tile, wood) directly up to the insert’s edge to achieve a perfect flush-mount look.

On-Site Mitigation: Preventing Finish Damage

- Heat Outlet Management: While the casing is ZC, hot air exhausts from the top heat outlet. To prevent the ”halo effect” (discoloration or warping of finishes), we advise using high-heat rated materials (e.g., stone or tile) or appropriate sealants directly above the outlet.

Ⅳ. Authority and Compliance: Global Certification and Quality

Your Global Compliance Passport: Safety and Supply Chain Assurance

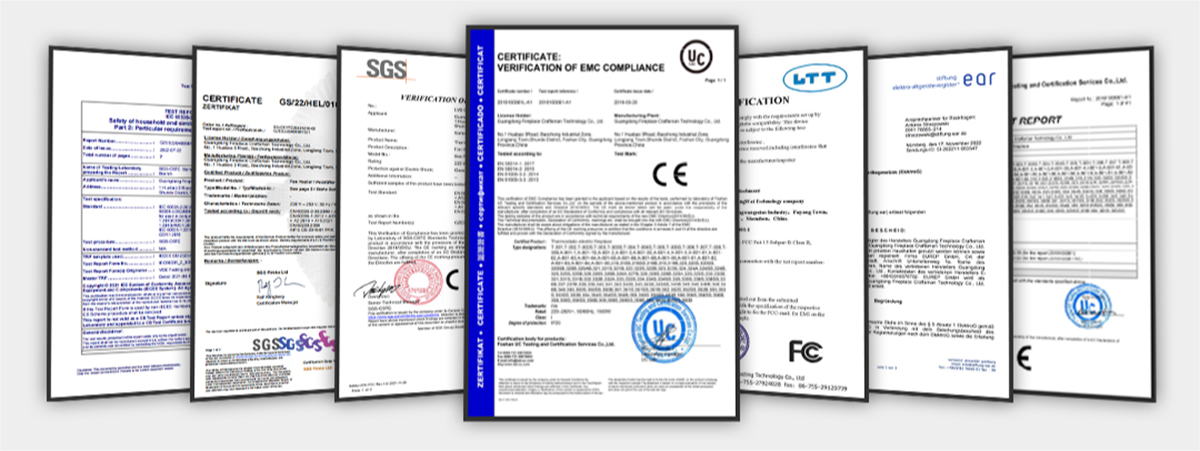

In the B2B sector, certification signals quality, safety, and operational reliability. Our comprehensive international compliance portfolio assures smooth project passage across major markets:

|

Authority Certification |

Value Proposition for Commercial Projects |

|

CE (EU) / UKCA (UK) / GS (German Safety) |

European Market Access. CE and UKCA are mandatory marks for the EU and UK. The GS mark (Germany’s stringent voluntary safety test) provides superior quality assurance valued highly by European developers. |

|

CB International / SAA / GCC |

Global Project Scalability. CB (IECEE) certification validates international electrical safety standards, accelerating local approvals like SAA (Australia/NZ) and GCC (Gulf States). |

|

LVD CER / EMC CER |

Technical Reliability. LVD (Low Voltage Directive) ensures electrical safety; EMC (Electromagnetic Compatibility) ensures the unit will not interfere with sensitive building electronics or Wi-Fi systems. |

|

RoHS / REACH / WEEE (Germany) / ERP |

Green Building Compliance.These environmental certificates guarantee restricted use of hazardous substances and compliance with European waste and energy efficiency regulations, supporting projects seeking LEED or BREEAM certification. |

|

ISO 9001 (Quality Management) |

Supply Chain Assurance. ISO 9001 demonstrates a commitment to consistent quality in manufacturing, delivery, and service—a crucial factor for managing large-volume, critical orders. |

Frequently Asked Questions (FAQ)

|

Question |

Answer |

|

Q: Does “Zero Clearance” mean I can install the unit directly against wood framing without any gap? |

A:Yes. Our CB, CE, and GS certifications guarantee that the external shell is approved for direct contact with standard combustible building materials (like drywall or wood studs) because the external temperature remains low. |

|

Q: Do your commercial ZC models require any venting or chimney system? |

A:No. All our electric fireplace inserts are 100% ventless. This greatly simplifies the design and eliminates the need for any costly chimney, flue, or dedicated ventilation system. |

|

Q: How do I prevent the primary wall finish (e.g., paint) from warping or discoloring near the heat outlet? |

A:Use heat-resistant finishing materials (stone, tile) or high-temperature rated paints and sealants immediately surrounding the heat outlet to mitigate the localized heat plume. |

|

Q: Can the heating element be run independently of the flame effect for year-round use? |

A:Absolutely. All our advanced models offer independent control. The realistic flame effect can be enjoyed for ambiance in the summer without activating the heater. |

Conclusion: Achieve Project Success with Certified ZC Inserts

The Zero Clearance electric fireplace is the definitive modern architectural solution. It eliminates the headaches of traditional installations while providing the highest levels of global compliance and safety assurance.

Take the Next Step:

- Contact Our Project Consultants today for a customized bulk-order quote and to begin planning your next high-efficiency development.

Post time: Nov-17-2025